Building Robots - System Integration

This is one of the 4 free courses at Extension School of TU Delft that was developed under the GEMS project. The courses are a part of learning program: Building Robots: from Mechatronic Components to Robotics.

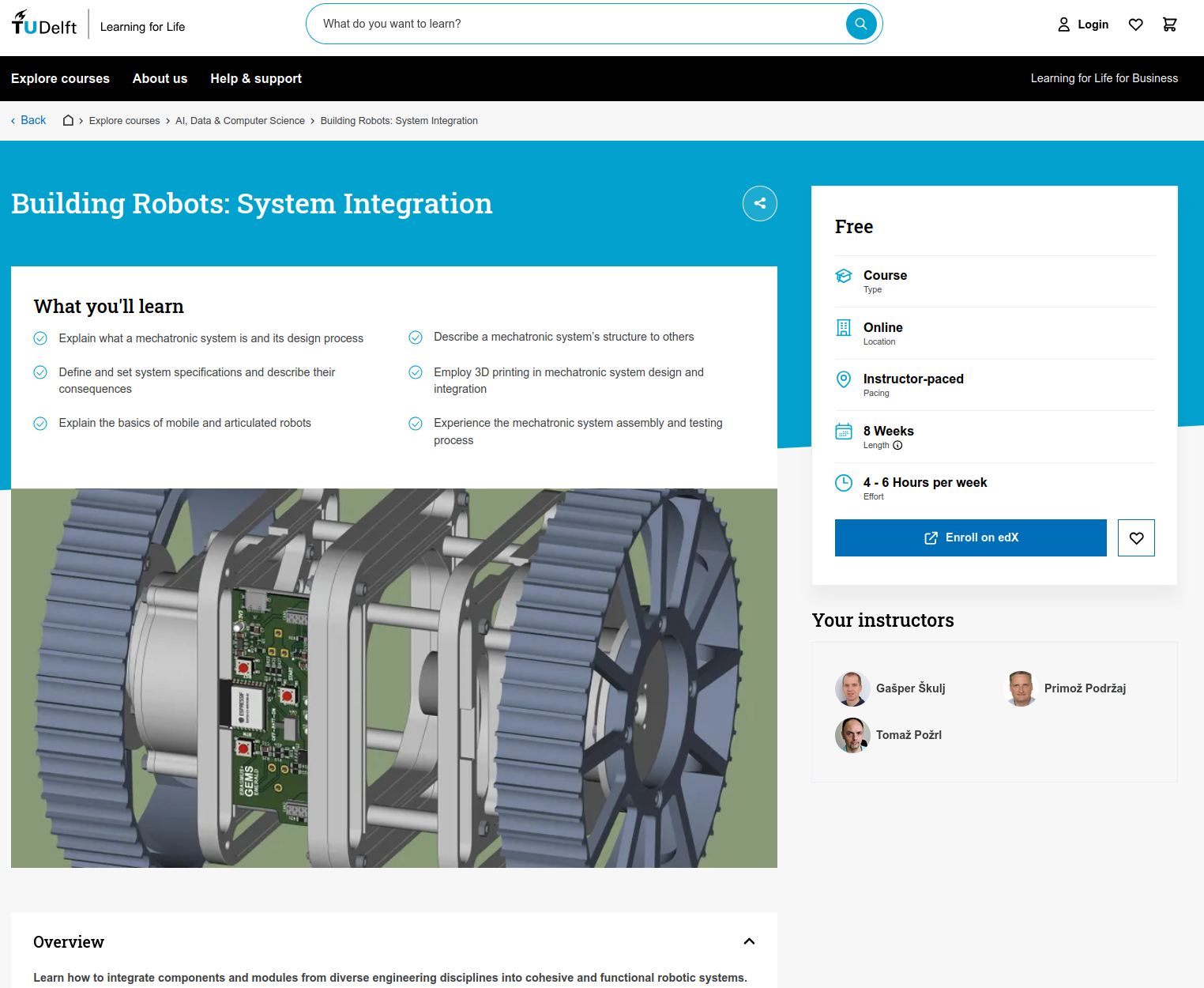

This course Building Robots: System integration is focused on the how to design and integrate mechatronics components into a simple robot. The course introduces the GEMS Emerald module, which is used to connect all GEMS modules and 3D-printed mechanical parts into wirelessly controlled mobile, articulated robots. You can access the course by enrolling with a free edX account.

# Course overview

This course covers essential knowledge and skills for system integration in mechatronics, with a focus on robotics. Mechatronic systems are increasingly shaping our world, with robots standing out as some of the most impactful examples. These versatile machines boost efficiency across various domains, from factories and farms to homes and even space exploration. At the core of robotics, electrical drives enable controlled motion, serving as the backbone of these systems.

This course addresses the challenge of integrating multiple engineering disciplines to design and develop robotic applications. Whether you’re a student, young engineer, or experienced specialist, it offers a starting point on the road to mastering robotic systems. Through practical examples and hands-on learning, you’ll acquire the necessary skills to conceptualize, build, and control mechatronic systems and robots.

It is the last course in the mechatronics MOOC programme titled Building Robots: From Mechatronics Components to Robots, developed by GEMS project partners, with the University of Ljubljana taking the lead in introducing you to robotics through system integration.

The course consists of eight modules, including an introductory module (Module 0). In Modules 1 to 7, you will have access to one lecture video with accompanying materials, a quiz, and a practical assignment.

Each lecture video presents an important concept of system integration in robotics and connects it with real GEMS educational equipment. The quiz expands the knowledge covered in the lectures by inviting you to independently gather additional information using provided materials, internet resources, or AI assistance. The practical assignment asks you to implement a “Hello world!”-type example related to the lecture content. The assignment heavily relies on additional materials and tools such as PCB schematics, CAD models, and tutorial documents. If you are pursuing the certificate, the assignment must be submitted and will be manually graded by the staff. Progression through the assignments will lead you from system specifications to a wirelessly controlled robot operating in semi-automatic mode.

Learning objectives

So, what will you actually learn in this course? At the end of this course, you will be able to:

- Work as an integrator in a multidisciplinary team of specialists

- Systematically approach mechatronic system design projects to understand the system as a whole

- Make design compromises between system specifications and the difficulty of implementation, which significantly influences design success

- Identify further study areas based on newly discovered interests or gaps in knowledge

Course

The course is organized in 8 modules. A brief summary of each unit is presented below. Detailed instructions and resources will be provided during the course.

Getting started with the course

In the Getting Started section you’ll get to know the course structure, get familiarized with the virtual learning environment, complete your profile, meet your fellow students and the moderator. These introductory tasks should be completed in the beginning of the course, after your first login.

Additional material: GEMS_Tutorials_System_Integration

Mechatronic system design

- Explain what a mechatronic system is.

- Explain the mechatronic system design flow.

- List concepts used in mechatronic system design.

- List common problems in mechatronic system design and explain why understanding them is important.

Participants will learn how to describe a mechatronic system.

3D printing - Enabling robot manufacturing technology

- Explain 3D printing, focusing on FDM technology printers.

- List common problems of FDM 3D printing and possible solutions.

- Explain the role of 3D printing technology in system integration.

Participants will learn how to prepare a design for an FDM 3D printed part.

Mobile robot with differential drive

- Explain the configuration of a mobile robot with differential drive.

- Describe how a mobile robot can be built.

- Calculate forward and simplified inverse kinematics.

Participants will learn how a mobile robot with differential drive is configured and how different variables influence its kinematics.

Articulated robot

- Explain the configuration of a simple articulated robot.

- Describe how an articulated robot can be built.

- Calculate forward and inverse kinematics.

Participants will learn how a simple articulated robot is configured and how different variables influence its kinematics.

Wirelessly controlled robot - Information flow

- Explain how a mobile robot can be controlled wirelessly.

- Describe the information flow for wireless manual control of a mobile robot.

- List components needed for robust wireless control.

Participants will learn how to establish responsive and robust wireless control over a mechatronic system.

Wirelessly controlled robot - User interface

- Explain why the user interface of a mechatronic system is important.

- Compare different user interface implementation possibilities.

- Explain the difference between native and web applications.

- Explain the difference between cloud and edge applications.

Participants will learn how to establish a simple edge-based web application for wireless control over a mechatronic system.

Wirelessly controlled robot - Control mode

- Describe different modes of operation for a mechatronic system.

- List design features that make robot operation safer.

- Explain the importance of planned extensibility and access to design information.

Participants will learn how to extend manual control of a mechatronic system with automated features.