Drivetrain

The Drivetrain: Rotate and Move

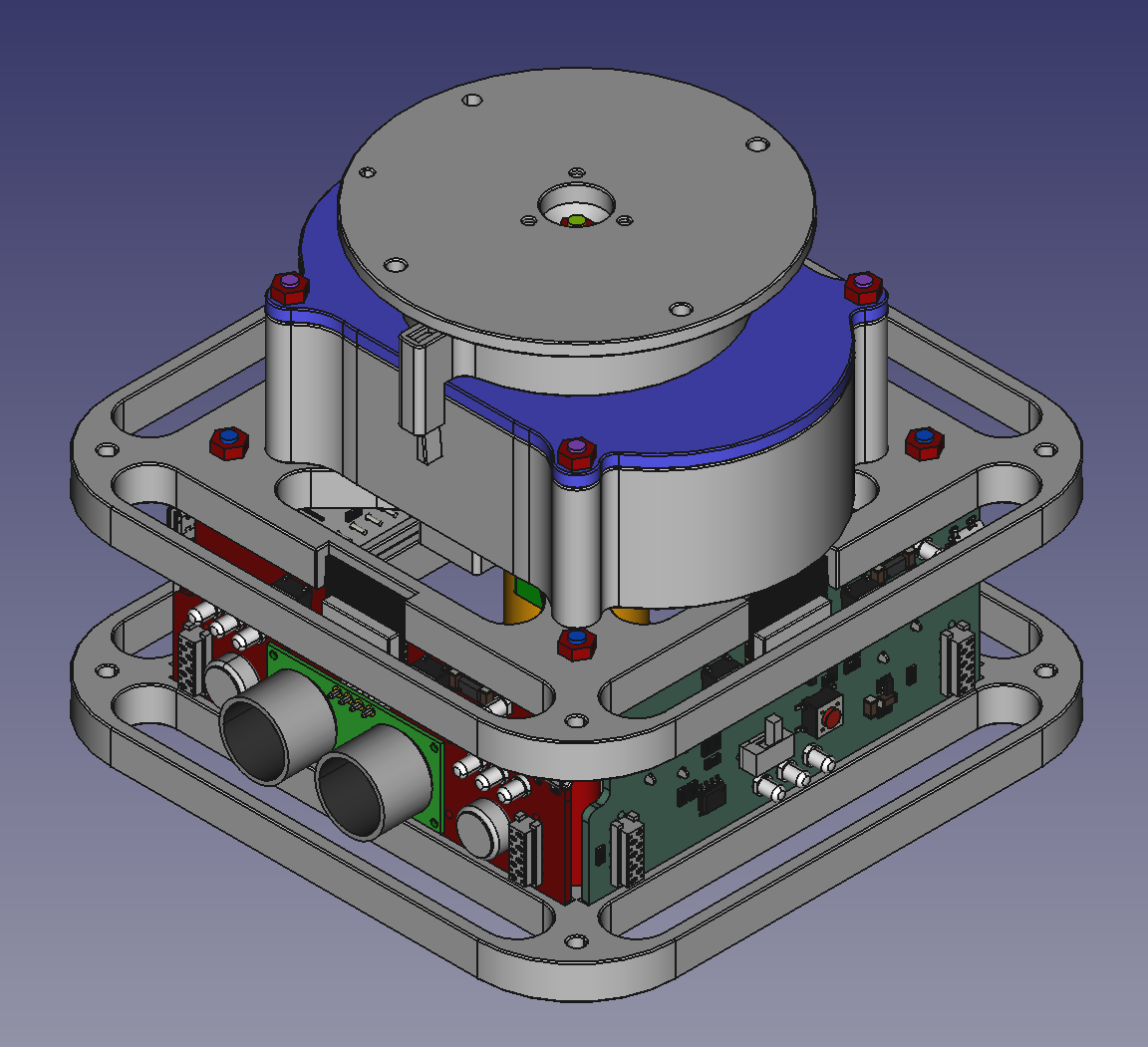

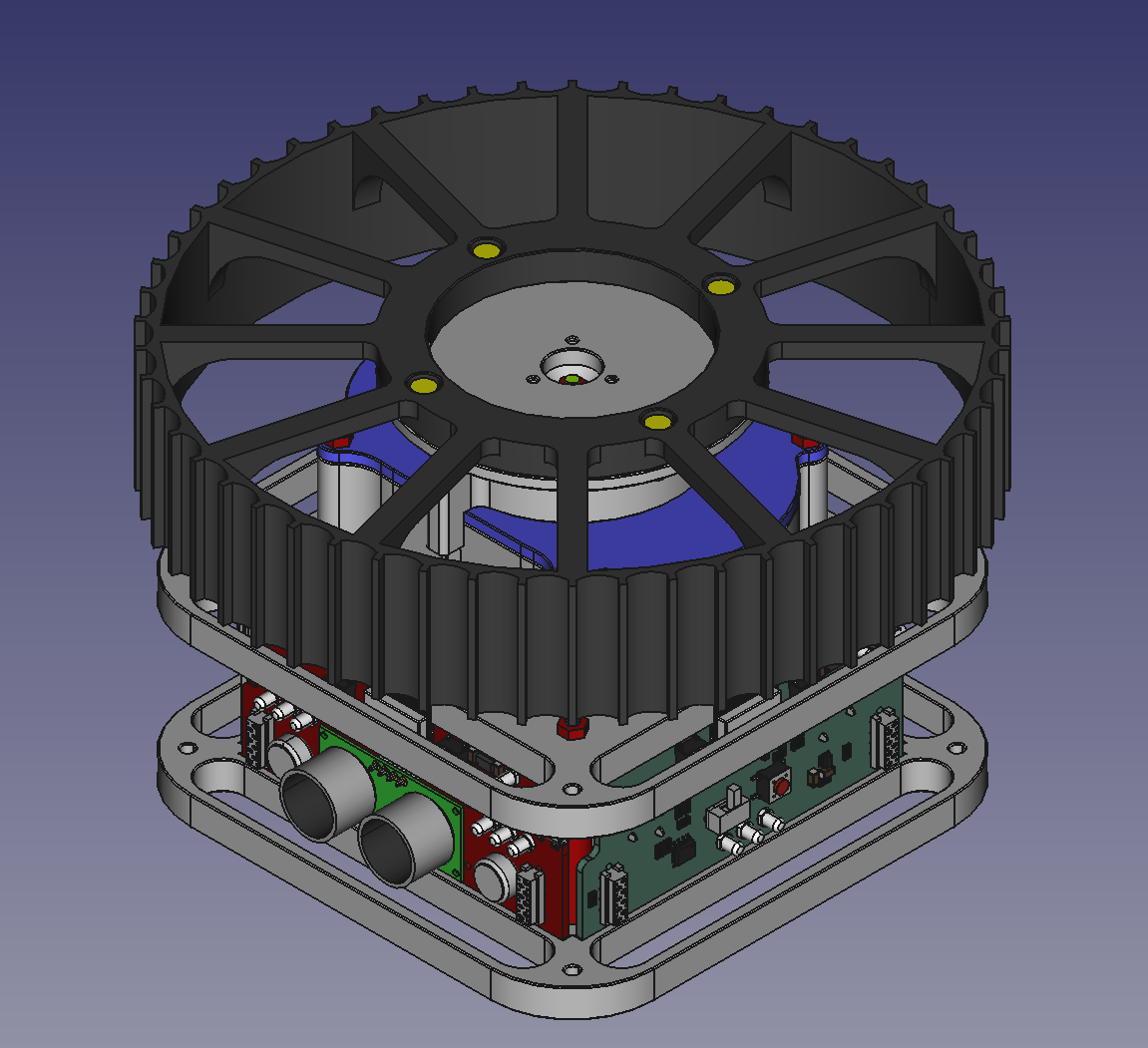

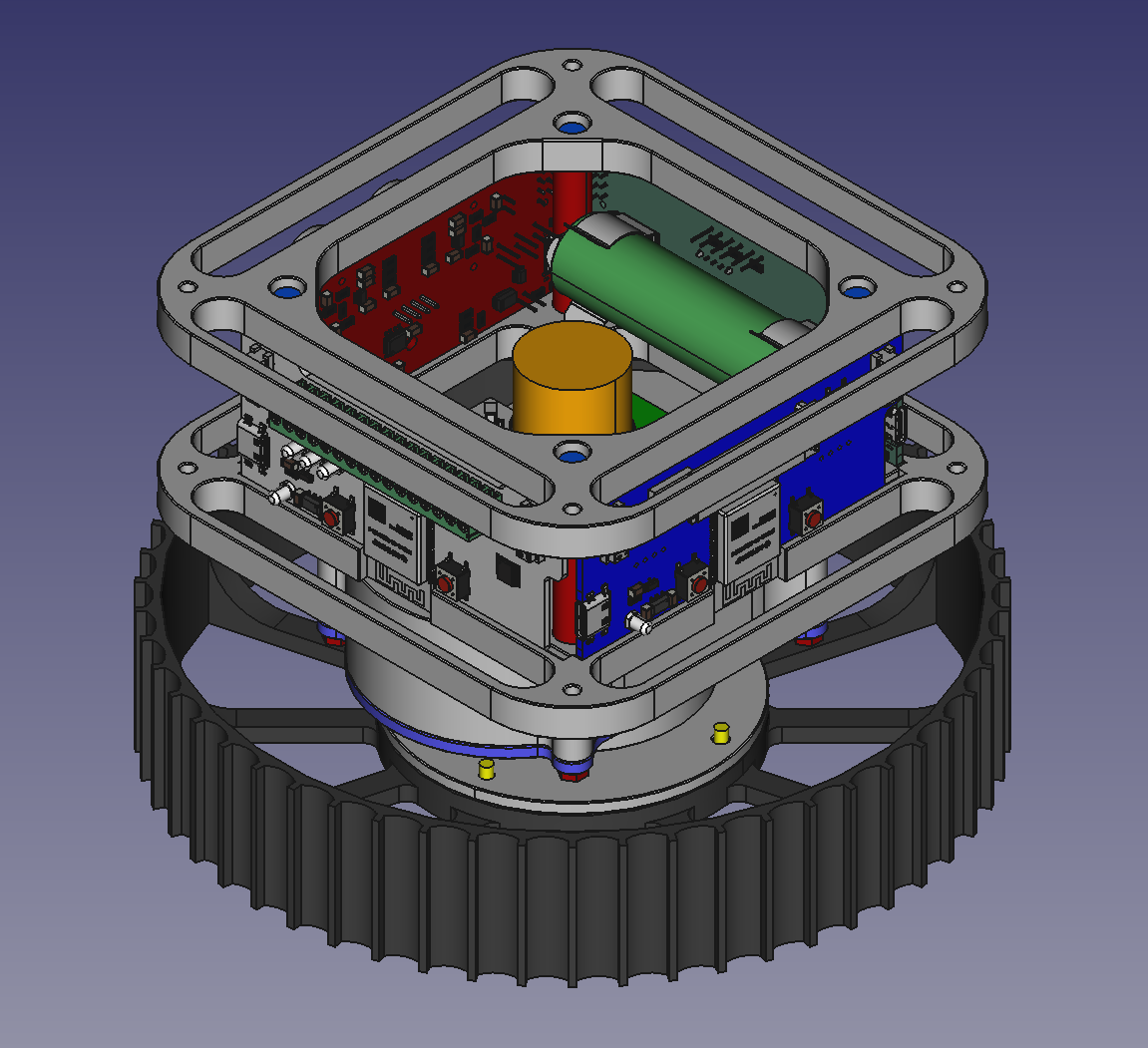

The GEMS drivetrain is a three-stage system designed for educational purposes, prioritizing understandability over efficiency. Parts are deliberately oversized, allowing for easier visualization and modification. Most components are 3D-printed using PLA filament on standard FDM printers, making them readily reproducible. Non-printed parts are standard mechanical parts (M3 screws and nuts, Φ3 dowel pins, Φ6 bearing balls).

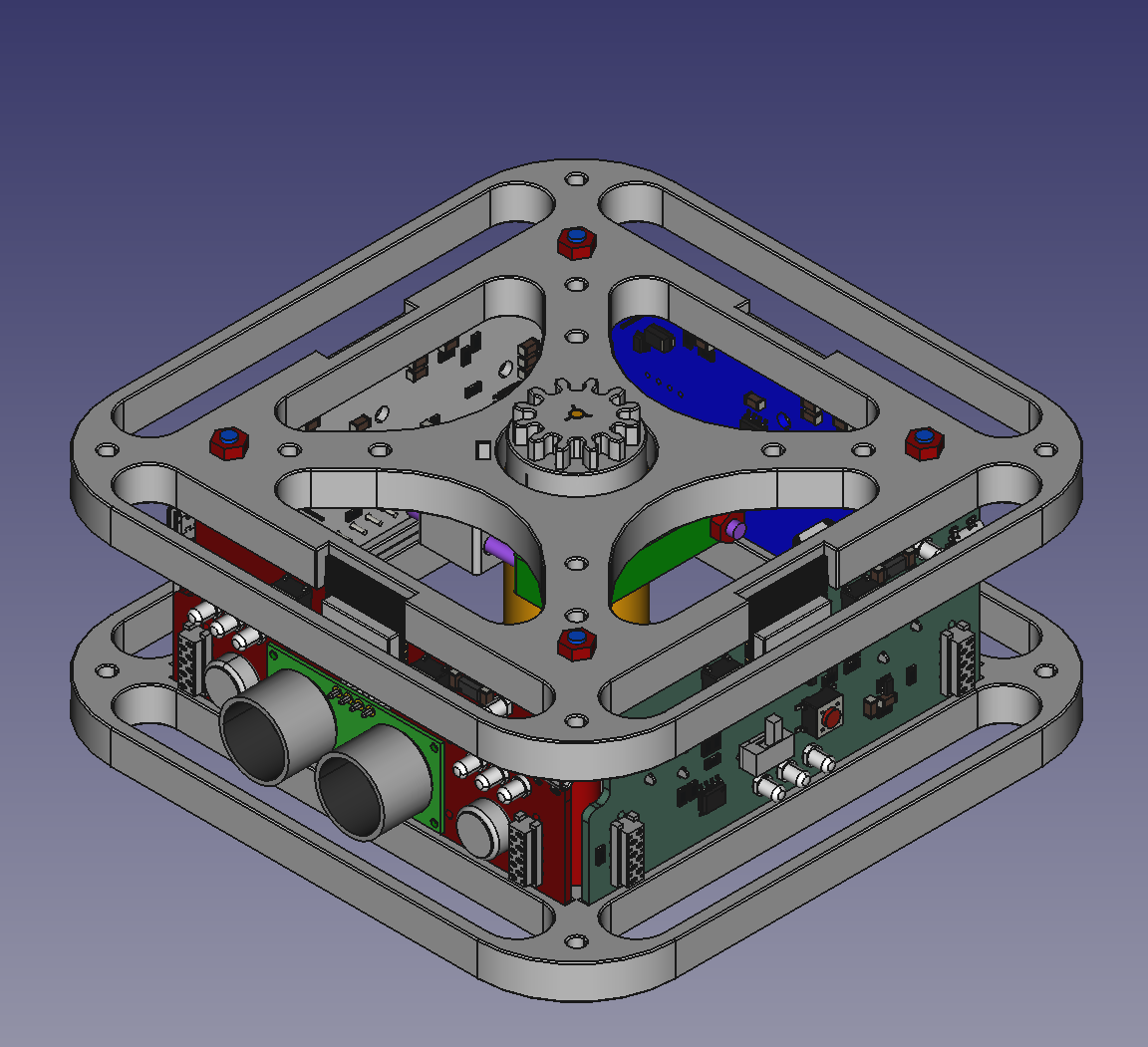

Stage 1 - Motor control: This stage combines the four main GEMS modules and the DC motor with its encoder. This stage can be used standalone, eliminating gearbox noise if needed.

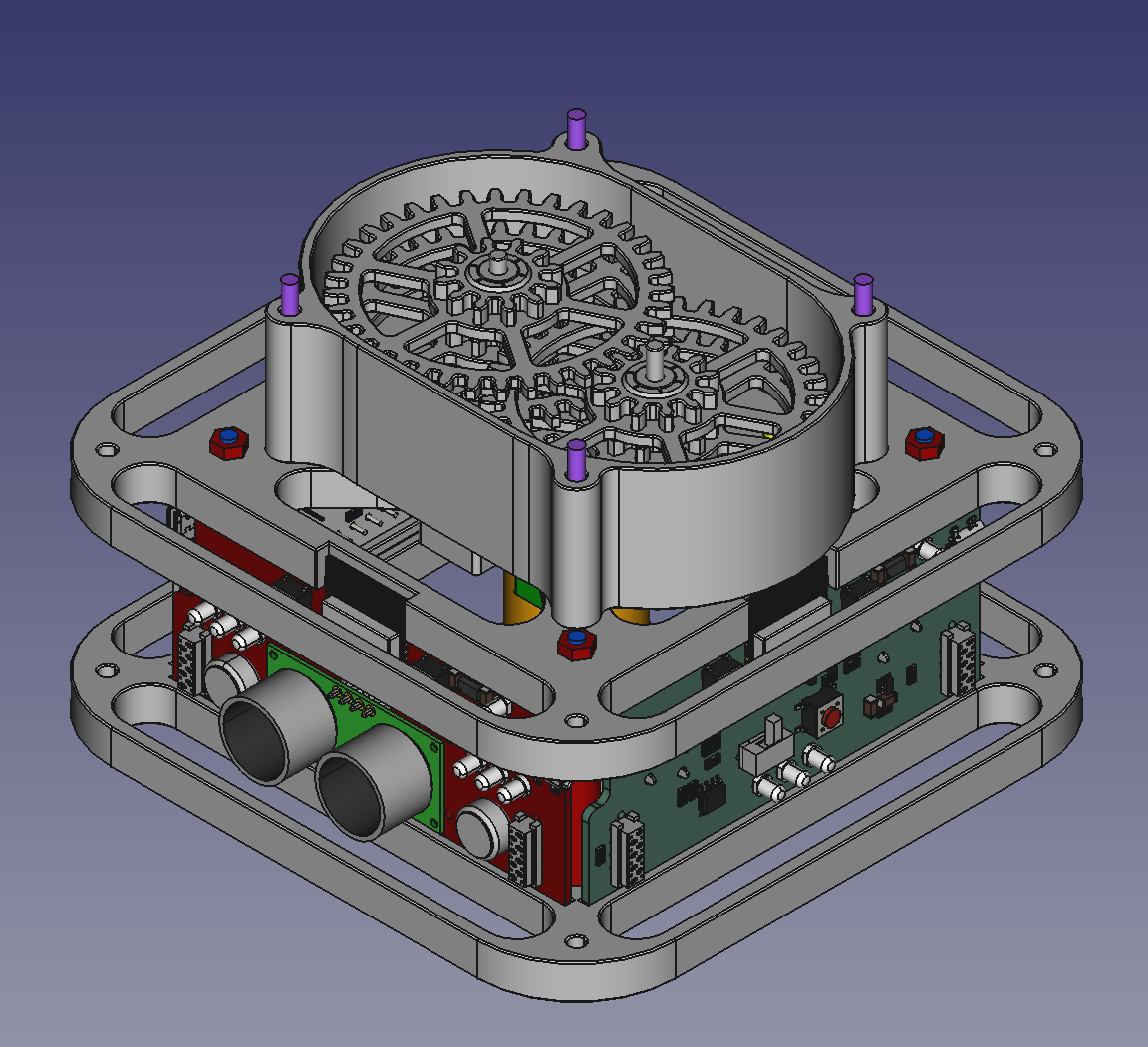

Stage 2 - Gearbox: The second stage consists of five sets of 3D-printed spur gears with a 3:1 reduction ratio in a housing. Here, the motor’s rotational speed is reduced, and torque is significantly increased (243-fold). This choice of gears (module 1.5, 14.5° pressure angle) combined with 3D printing contributes to a higher noise level, particularly at higher speeds. However, this allows for clear observation of how gear quality and tolerances affect drivetrain vibration and acoustics.

Stage 3 - Output: The final stage utilizes a custom-built radial ball bearing on the output shaft. On the output shaft a wheel or a holder can be mounted.

Lubrication: While not ideal, the drivetrain uses petroleum jelly (Vaseline) for lubrication. This choice prioritizes safety (skin-safe and non-staining) over optimal performance.

Features

- 3D printed PLA parts (FDM)

- Standard parts (steel)

- Spur gear: module 1.5, 14.5° pressure angle

- Radial ball bearing

- Lubrication: petroleum jelly (Vaseline)